|

|

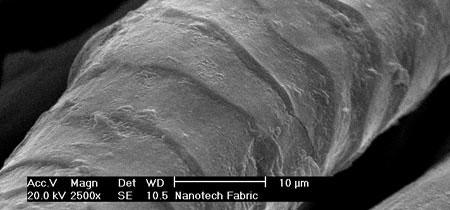

MICROTEX: Analysis and Investigation of Fibres and Textiles Also Dusts, Papers, Particles, Contaminants Principal: Dr Phil Greaves, C.Text.FTI; Dip. RMS |

|

Expert Problem Solving |

Microtex

is an Analytical and Investigative Specialist Service for |

35 Years Experience |

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

| Microtex Reports are

used by Manufacturing Industry, Test Houses, Retailers, Private Consumers, Trading Standards, Lawyers, Insurance Assessors |

|||||||||||||||||||||||||

TECHNICAL

INVESTIGATION - ANALYSIS - MICROGRAPHY -

IDENTIFICATION - QUALITY ASSESSMENT FORENSIC - LITIGATION - TRAINING |

|||||||||||||||||||||||||

| ©2013 microtex-analysis.com |